Conference presentation at: ICORR 2025, Chicago (USA) 12-16 May 2025

DOI: 10.1109/ICORR66766.2025.11063034

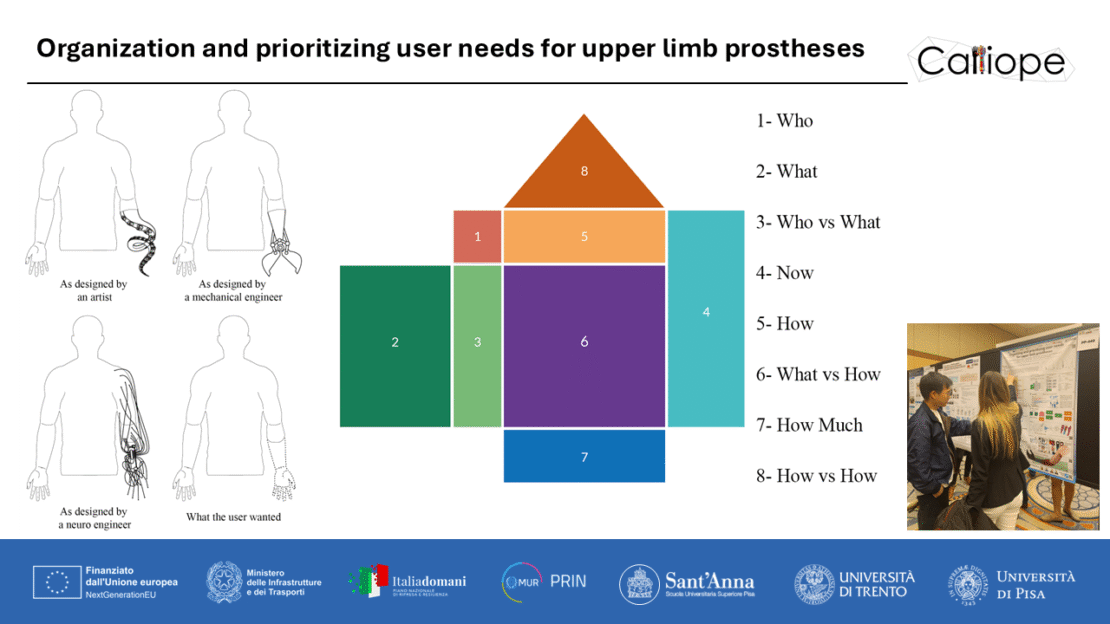

Organization and prioritizing user needs for upper limb prostheses

Upper limb amputation leads to severe restrictions in daily activities and psychosocial difficulties, which can dramatically reduce the quality of life of affected people. Despite the significant scientific and engineering effort in building advanced robotic prostheses, their abandonment rates suggest a discrepancy between user needs and device performance. To address this gap, we present an initial step in identifying, harmonizing, and prioritizing the needs of people with limb loss. Using the PRISMA methodology, we analysed 73 papers on the topic. Using a bottom-up approach, we clustered the needs identified in different surveys into categories and macro-categories based on a taxonomy derived from the terms identified in the literature. We then prioritized the needs after a normalization of the major surveys. We believe that this work will provide both a high-level and low-level understanding of the needs of people with limb loss, thereby helping to guide the design of more user-friendly prostheses. In the future, combining these results with the definition of technical specifications will enable the identification of needs that can be satisfied through personalized design, particularly considering recent advances in manufacturing processes.

Conference presentation at: GNB 2025, Palermo (Italy) 16-18 June 2025

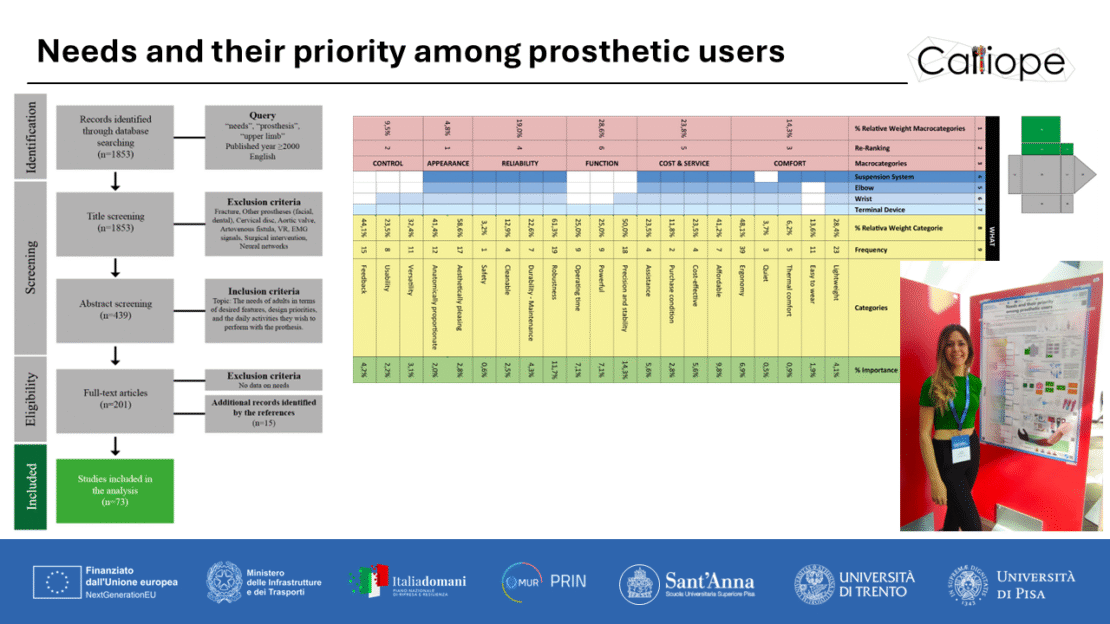

Needs and their priority among prosthetic users

Upper limb amputation imposes severe limitations on daily activities and psychosocial well-being, significantly reducing the quality of life for affected individuals. Despite extensive scientific and engineering efforts in developing advanced robotic prostheses, high abandonment rates indicate a gap between user needs and device performance. To address this issue, we take an initial step in identifying and prioritizing the needs of people with limb loss. Using the PRISMA methodology, we analyzed 73 relevant studies. Employing a bottom-up approach, we categorized user needs into structured taxonomies derived from the literature. We then prioritized these needs by normalizing findings across key surveys. We believe this study provides both a high-level and detailed understanding of the needs of individuals with limb loss, offering valuable insights for designing more user-centered prostheses. In the future, integrating these findings with technical specifications will support the development of personalized prosthetic solutions, particularly by leveraging recent advancements in manufacturing technologies.

Conference presentation at: Materials Today conference 2025, Sitges (Spain) 23-26 June 2025

https://www.elsevier.com/events/conferences/all/materials-today-conference

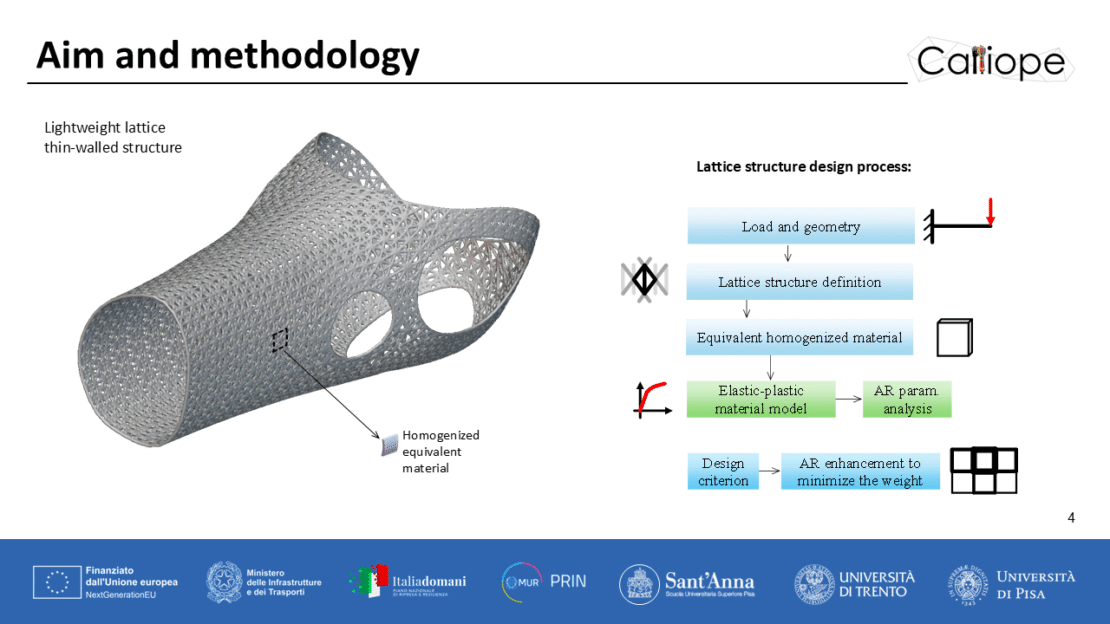

Elastic-plastic homogenization of polymeric thin-walled lattice structures for prototypal structural applications

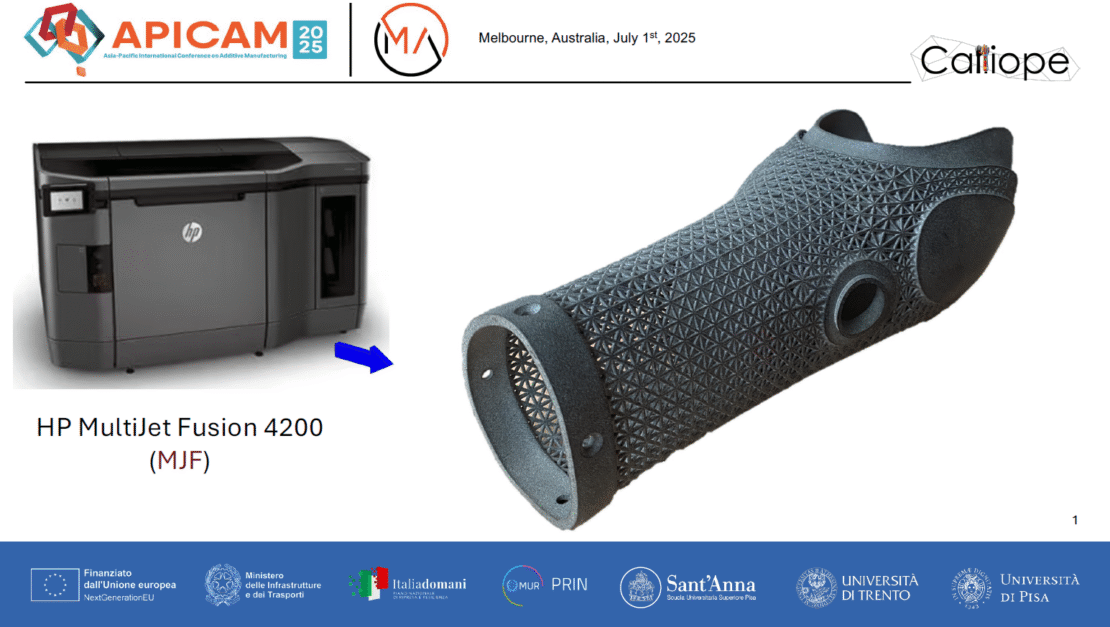

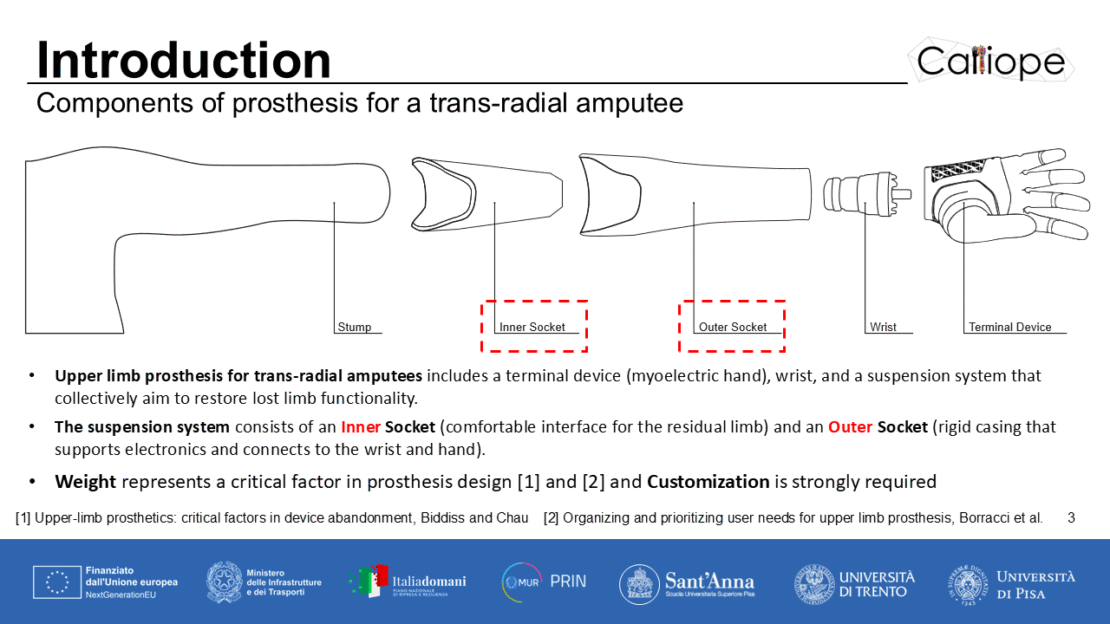

Conference presentation at: APICAM2025, Melbourne (Australia) 01-03 July 2025

https://www.apicam2025.com.au/

Keynote speaker: Matteo Benedetti

https://www.apicam2025.com.au/keynote-speakers.html

Design and Additive Manufacturing of a Lattice-Based, Ultra-Light Forearm Prosthesis

Conference presentation at: Sim-AM 2025, Pavia (Italy) 9-11 Semptember 2025

Homogenization of Polymeric Thin-Walled Lattice Structures under Elastic-Plastic Loading

Conference presentation at: I-RIM 2025, Rome (Italy) 17-19 October 2025

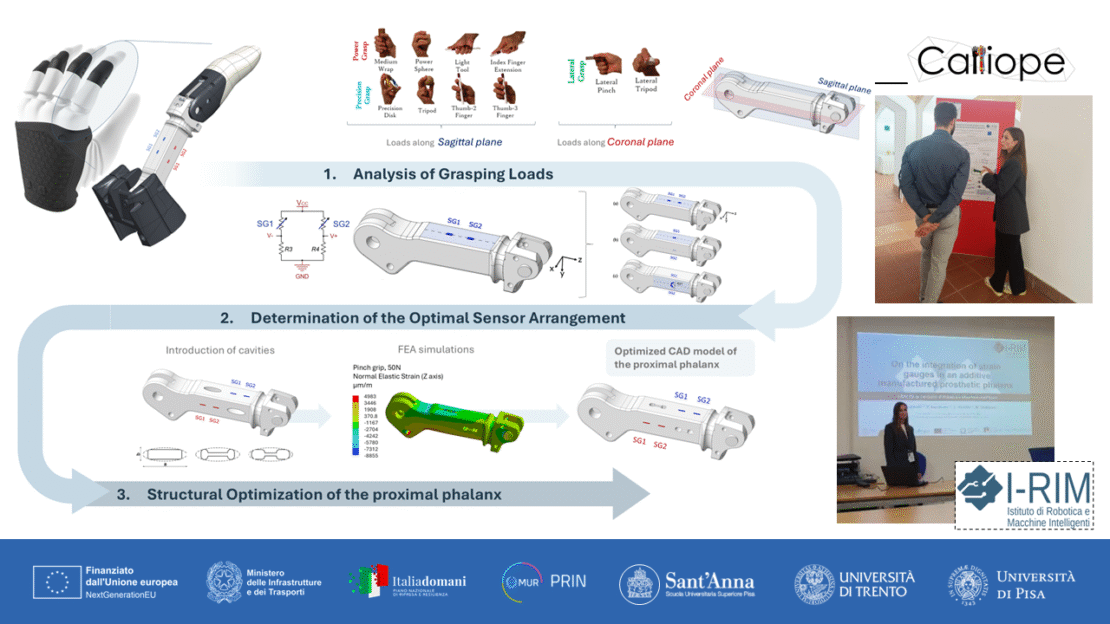

On the integration of strain gauges in an additive manufactured prosthetic phalanx

Lack of tactile feedback remains a major limitation in prosthetics, restricting manipulation accuracy and increasing cognitive effort during daily activities. For this reason, modern artificial hands must be endowed with force or tactile sensors. A key question is whether additive manufacturing plastic structure can themselves host load sensing elements. Here we investigate the integration of semiconductor strain gauges into an additively manufactured proximal phalanx of a prosthetic finger as a structural sensing approach for force estimation. We propose a methodological framework to identify the optimal sensor configuration, ensuring independence from the contact point as well as robustness to finger posture variations. The phalanx was further refined with cavities that concentrate strain in the sensing regions, enhancing measurement sensitivity and overall system effectiveness. Finite element simulations guided the structural optimization and assessed sensor performance under representative loads. Ongoing efforts focus on the experimental validation, with the potential to establish structural additive manufacturing sensing as a potential solution for affordable, personalized prosthetic hands with integrated tactile feedback.